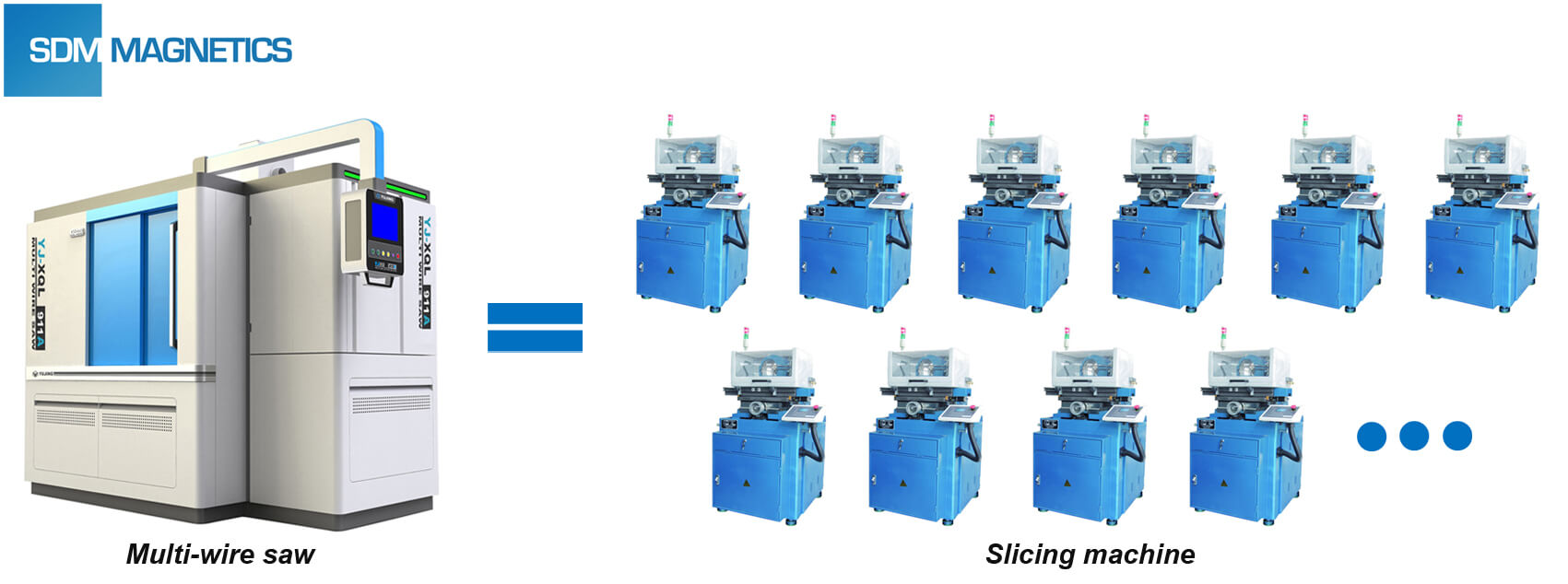

For years multi-wire saw has been used for the machining of hard brittle material, such as silicone, semiconductor and sapphire, and gradually took the place of traditional inner slicing machine. Multi-wire saw is also introduced to the machining process of rare earth permanent magnet by Chinese manufacturers, and achieved good results.

In order to reduce the cost of material, cost and energy, SDM Magnetics has also purchased multi-wire saw recently. SDM Magnetics has long been committed to the internal continuous improvement!

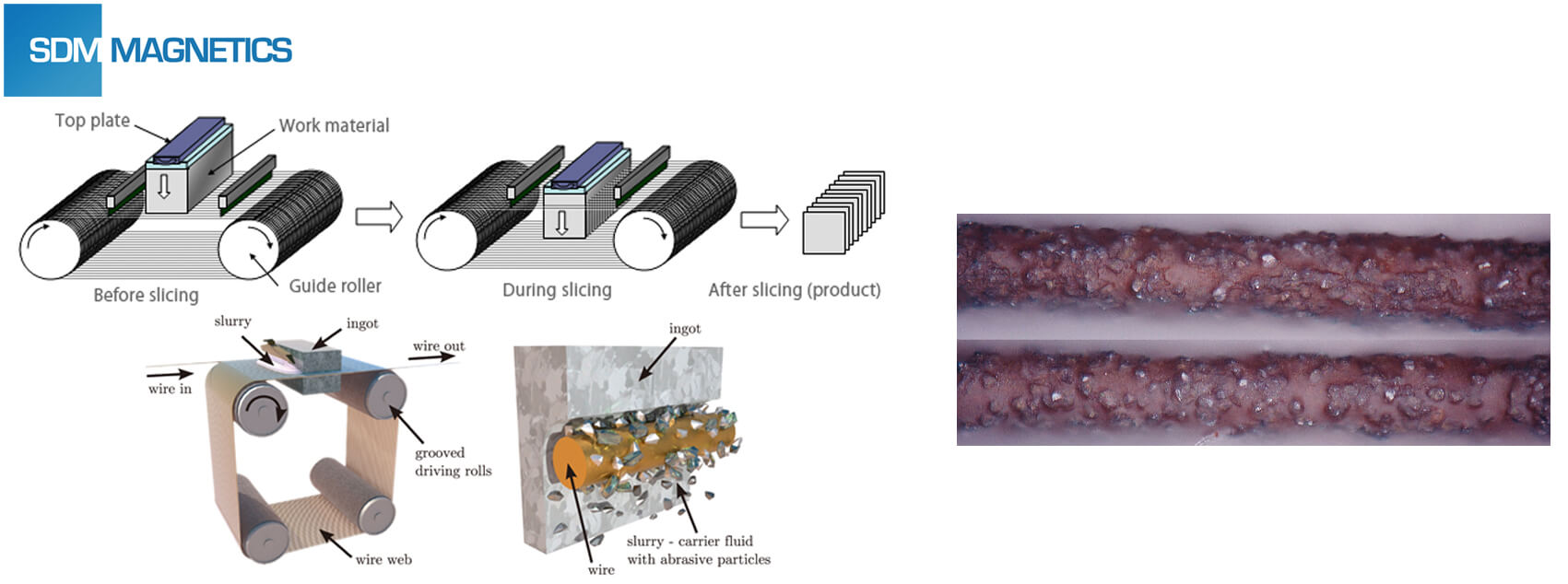

Working Principle of Multi-wire Saw

Multi-wire saw depend mainly on reciprocating motion of thin steel wire, then enable grinding and cutting for material. Due to the environmental item, Silicon Carbide mortar has virtually been abandoned by users, and resin bonded diamond line has become mainstream.

Advantages of Multi-wire Saw

- Materials savings.

- Cutting time of multi-wire saw much shorter than traditional slicing machine, and hundreds of partscan be machined simultaneously.

- Superior cutting precision with good consistency.

- Surfaceroughness is low, and free of follow-up grinding process and its machining allowances.

- Sludgescraps easy to recycle.